|

HOME STUDIO Cool DIY Plan: How To Air Condition Your Voice Over Home Studio Recording Booth  By Greg Thomas By Greg ThomasVoice Actor WARNING:

The following contains graphic pictures of exposed duct work that may

not be suitable for those who are sensitive to interior design or

practice feng shui. This project also comes with the potential for a low

spousal approval rating. Check with your significant other before

proceeding. Scorching temperatures, often over 100°F, might again hit much of the U.S. this summer. These unusually hot weather

conditions have caught most of the country by surprise.

For those of us in Texas, though, it's business as usual. Summertime

temperatures above the century mark, sometimes for a week or more, are

common all over the state from June to August.

If you've never experienced a Texas summer, it's hard to imagine what

it's like living with that kind of heat on a daily basis. A LITTLE SWEAT BOX You may have heard (or know from

experience) that an isolation booth can quickly turn into a little sweat

box, especially in the summer. The computer fan and dryer hose that

typically come with a booth just can't keep up with torrid summertime

heat. I've heard both male and female voice actors tell of recording in

only their underwear because their booth was so hot. Even if the booth starts out at a moderate temperature, after you're

in there for 20 or 30 minutes, your body heat alone will cause the

temperature to rise significantly. And if all you're doing is pulling

room-temperature air into a heavily insulated booth in the summertime,

it's a losing battle. Your body heat can't get out fast enough, and the

isolation booth turns into a padded dry sauna. COOL IDEA ... WHAT IF? One hot summer day, I was sitting at the desk outside my VocalBooth®* while

the air conditioner was blowing cold air onto my balding head.  The cold

air must have kicked my brain cells into action, because it got me to

thinking ... The cold

air must have kicked my brain cells into action, because it got me to

thinking ... What if I could find a way to get some of that 60°F air out of the vent in the ceiling ... and route it to the ventilation duct in my booth?  Would that cool off my booth? Would it bring an end to soaked arm

pits, sweat-stained scripts, and repeatedly opening the door of the

booth to try to cool off? There was only one way to find out.

Build something (I didn't know what just yet,) and see if it worked. LEFTOVERS ARE A WONDERFUL THING A few years earlier, in what turned out to be a futile attempt to cool

the booth by getting more air into it, I enlarged the ventilation hole

from 4 inches to 6 inches, and pushed room air into the booth through a

Panasonic FV-15VQ5 WhisperCeiling 150 CFM Exhaust Bath Fan that I'd

bought to replace the ineffective computer fan.  The booth was connected to the fan with Quietflex duct.

(Be careful opening this stuff. It tends to come out of the wrapper like one of those spring-loaded snakes in a can.) The booth was connected to the fan with Quietflex duct.

(Be careful opening this stuff. It tends to come out of the wrapper like one of those spring-loaded snakes in a can.) Since I had plenty of Quietflex left over, I just needed a way to tap

into the ceiling vent and get the cold air to the fan. After a

long-distance call to a good buddy who used to run his own air

conditioning company, I knew I had a plan. AND HERE'S THE PLAN

... The plan was to remove the grille from the ceiling, and build a

plenum (that's a fancy HVAC word for box) that fits inside the duct box

where the air comes out. Then, cut a hole in the plenum for a grille to

ventilate the room, and another hole to connect to the existing Panasonic fan. I already had most of the materials on hand that I thought I would need,

which is why I was able to pull this off so cheaply. I only had to buy a

little bit of plywood, some clamps, a titanium drill bit to cut through

the metal duct box in the ceiling, a hole saw kit, paint, glue,

anchors, and some round adapters. (You'll find a complete list, with

prices, at the end of this article.) THE DUCT BOX  I used 15/32 inch plywood to make a 10" x 6" box duct box in the ceiling. It hangs

down 2'feet from the 9 foot ceiling. I used 15/32 inch plywood to make a 10" x 6" box duct box in the ceiling. It hangs

down 2'feet from the 9 foot ceiling. To minimize leaks, it's

deliberately a very tight fit, but it's also attached to the ceiling

with expansion bolts just to be sure it doesn't fall out.

(If you decide to build a plenum, remember the old rule: measure twice, cut once. Or in my case, measure 3 or 4 times.) After I built the plenum, I cut a 10" x 6" hole in the front

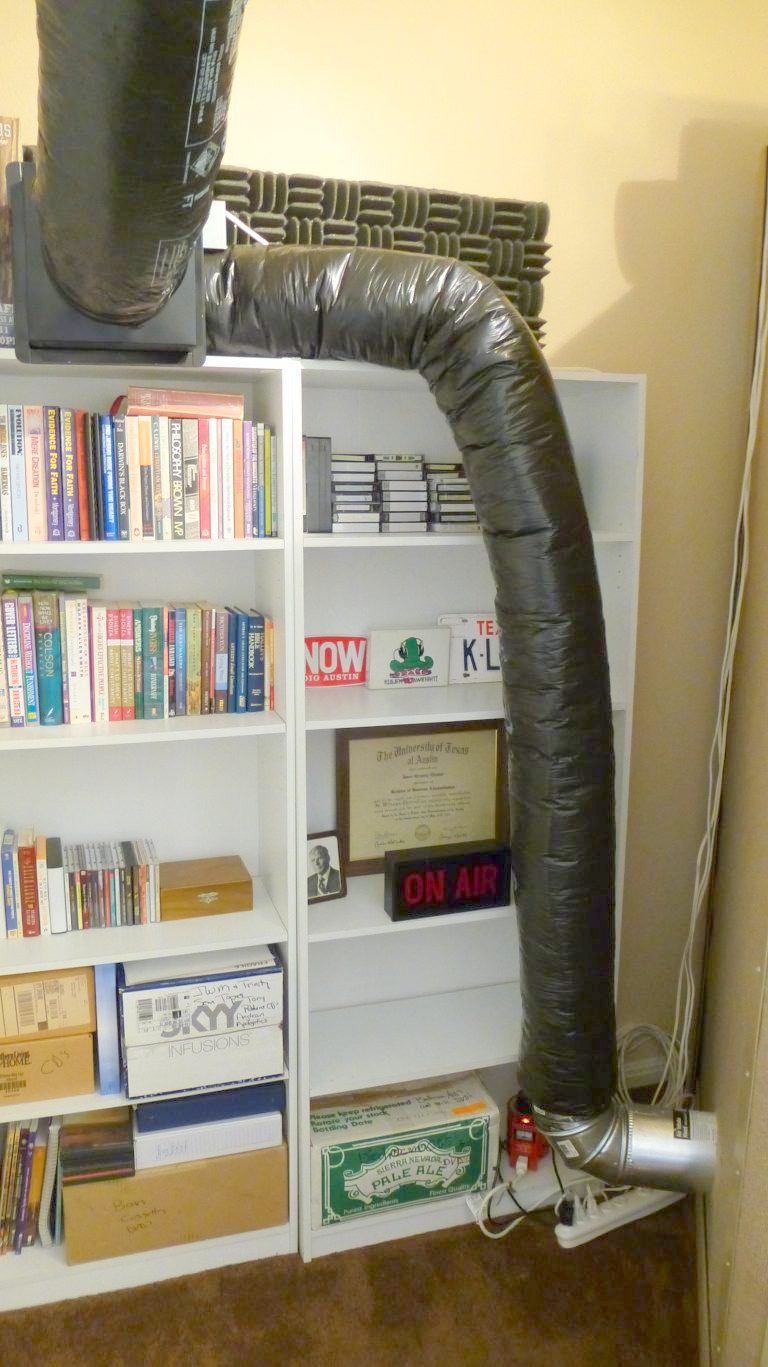

to mount a grille, and cut a 4" hole in the side for the 4" to 6" round adapter that connects it to the Quietflex. ALL HOOKED UP  Here's how the system looks all hooked up. Here's how the system looks all hooked up.

SO, HOW WELL DOES IT WORK? SO, HOW WELL DOES IT WORK? Beyond my wildest expectations !!! We try to keep our thermostat at 77°F in the summer, and at 80°F when

we're not at home. So before I built the plenum, the temperature inside

the booth was typically about 82°F.

But that was before I got in there and started voicing scripts.

After I'd been in the booth for 15 or 20 minutes, I was sweating away

because the temperature was up to 88°F. That's a 6 degree rise in only

20 minutes.

Just from my own body heat. Now, with everything connected, I can step into a pleasantly cool

76°F booth, and the temperature does not rise during a session. Instead

of working in an 88°F booth, I now work in a 76°F booth. That 12 degree difference is HUGE.

And if I set the house thermostat on 75°F, I can get the booth down to 70°F. FAN IS QUIET ENOUGH I thought I might have to close off the white grille in the front in

order to force enough air into the booth to keep it cool, but I don't.

The Panasonic fan pulls enough cold air into the booth without closing

the grille, so both the room and the booth stay cool. And since I'm using the same fan to ventilate the booth that I did

before, the noise floor hasn't changed. My VU meter still bounces around

between -54db to -57db when normalized to -3db. Not Hollywood recording

studio quiet, but quiet enough to keep my clients happy. And yes, I know: for a lower noise floor, I really should build a

proper baffle box instead of connecting the duct work directly to the

booth. But I don't have issues with noises getting in through the duct.

(Not even the psycho barking dog across the back fence.) So I'm not sure

how much improvement I would see in the noise floor by building one. But all of this was designed as a test of concept anyway. If it

didn't work, I wouldn't be out an arm and a leg, and if it did work, I'd

be cool.

And for a guy who never was one of the cool kids growing up, being cool is a big deal. THE MATERIALS AND COST Here's a list of the materials I used and their costs at the time of construction. Most items cost more now:

That's a total of $109.98 + 8.25% sales tax = $119.05. I already owned a drill and a jigsaw. REDUCE, REUSE, RECYCLE Of course, one of the reasons I was able to chill out so cheaply was

that I already had the Quietflex duct, the Panasonic fan, and a Variac

left over from my previous attempt to cool off the booth. You may be

able to keep costs down and tie your current booth into an air

conditioning duct using something similar to the design I created. The

Panasonic fan I'm using has been discontinued and replaced with a three

speed model. I'm assuming it's a better unit, but can't guarantee that.

You'll still need a Variac transformer to slow it down, though. Here

are sources for the Panasonic fan, the Quietflex duct, and the Variac

transformer:

All prices are plus shipping. You will also need a 3-prong extension

cord to connect the fan to the wall socket. Cut the socket off of the

extension cord and hard wire the cord to the fan. Because there is too much wind noise with the Panasonic fan running

at full speed, I slow the fan down to half speed with a Variac

transformer. If you decide to slow your fan down, do not use a standard

light dimmer to slow it down. A light dimmer won't keep the electricity

at 60 Hz, and it will eventually burn out the fan motor. A Variac

prevents this. *VocalBooth® is a registered trademark of VocalBooth.com, Inc. -------------------- ABOUT GREG Greg

Thomas, aka the Deep, Warm Voice, lives in San Antonio, TX with his

wife and an extraordinary standard poodle. Greg is a recovering

broadcaster who has been voicing scripts to inform, sell, and persuade

audiences in the U.S., Canada, Europe, China, and the Middle East for over

25 years. He has been recording VO from his professional home studio

for more than 10 years. In

his life before freelance voice over, Greg owned and managed a 100,000

watt radio station that he built from the ground up when he was 32. He

won 13 local Addy awards while he managed the station. His

VO clients include Verizon, Brawny Paper Towels, University of Notre

Dame, Irwin Vice Grip, Wounded Warrior Project, New York Red Bulls

Soccer, CSX Transportation, DuPont Pioneer, and Brugal Rum. When he's

not behind the mic or editing, he drives his wife, kids, and grandkids

crazy with his Dad jokes. Email: greg@DeepWarmVoice.com |

Tell Us What YOU Think!

Please Note: Since we check for spam, there will be a slight delay in the actual posting of your comment.

Comments

No comments have been posted yet. Hurry, and you could be the first!

.png)

click for new article alerts